Thickness: 0.025~0.08MM, regular 0.035,0.045mm

Width: 500~2000mm Conventional 1000,1600,2000mm

Length: 100~1000M Conventional 200M, 500M

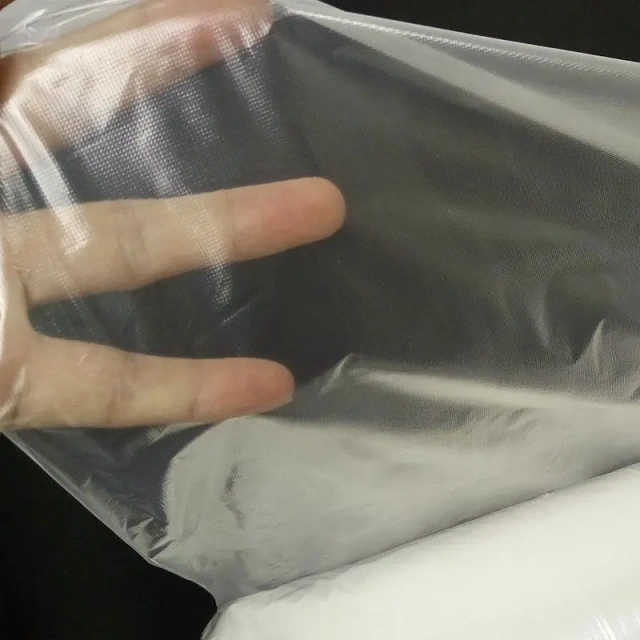

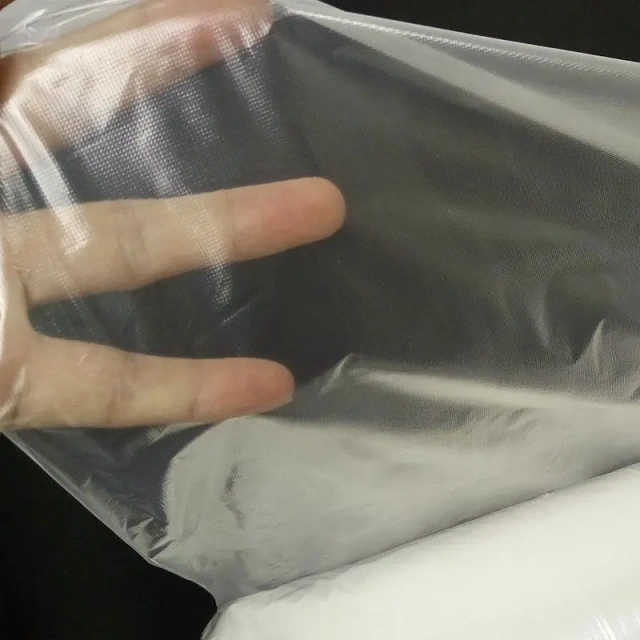

Product appearance: embossed on the front and light on the back

Color: natural color, translucent, white, colored, etc. (black, red, yellow, white, blue, green and other colors can be customized)

① The cold water soluble film cushion has excellent softness when applied to the bottom of the embroidery, and the hand feel is exactly the same before and after the embroidery.

② The color of the cloth and thread after the embroidery is dissolved in water is completely the same as before, and will not change color.

③ Cold water dissolving film can fully meet the strength requirements of various embroidery processes on the bottom.

④ Environmental protection without any side effects, no formaldehyde dissolved into plant starch, water and carbon dioxide.

⑤ The dissolution rate is fast, and it can be completely dissolved in normal temperature water at 15 ℃ for 5-18 seconds.

⑥ Cold water soluble film can be applied to all kinds of underwear, fashion and special fabrics.

Water soluble film embroidery has two methods, one is called lace, the other is called vacuum embroidery. Water soluble film is divided into two types, one is cold water, which will dissolve in water after soaking in cold water for about 24 hours; The other is hot water dissolution, which requires boiling with hot water above 80 ℃ Lace has no base cloth. Embroider directly on the water-soluble film, and then do post-processing to remove the water-soluble film, leaving only the embroidery thread Girls often use lace in their underwear Sometimes, the decorative flowers also used on the chest are embroidered. After failure, the post-treatment is done to remove the water-soluble film. The embroidery thread will bulge, but the middle is empty!

The low temperature water-soluble film can be dissolved in water at normal temperature (15 ℃ - 30 ℃) for 30 seconds (if the water volume is large and the fluidity is good, it will be faster), and it will be completely dissolved in 2 minutes. There is no residue on the embroidery and no harmful substances will be produced. It is a good product for table cloth embroidery, lace, mesh cloth and Pi cloth. The water-soluble film has almost completely replaced the traditional hot boiled (high temperature) water-soluble paper lining. The traditional hot boiled (high temperature) water-soluble paper lining can only be dissolved at a temperature of more than 60 ℃ in general, and the finished embroidery products are prone to wrinkle after hot boiling, which makes some products appear discolored, time-consuming and unsightly. It is more convenient than the traditional hot boiled (high temperature) water-soluble paper lining, and can be completely dissolved at room temperature, and can greatly reduce the rate of defective embroidery products.

|

|

Thickness: 0.025~0.08MM, regular 0.035,0.045mm

Width: 500~2000mm Conventional 1000,1600,2000mm

Length: 100~1000M Conventional 200M, 500M

Product appearance: embossed on the front and light on the back

Color: natural color, translucent, white, colored, etc. (black, red, yellow, white, blue, green and other colors can be customized)

Precautions:

1. The dissolution rate depends on the film thickness, water temperature, water volume, fluidity and other factors. Generally speaking, the thicker the film, the slower the dissolution rate, and the higher the water temperature, the faster the dissolution rate,

The larger the water volume is, the faster the dissolution rate is, and the faster the water flow is, the faster the dissolution rate is;

2. When not in use, it shall be sealed and packaged to prevent moisture absorption and wrinkling;

3. The film has front and back sides. The front side is bright and the back side is dim. It is preferred when used. When used in embroidery, the reverse side is downward with good effect.

4. The film is resistant to mineral oil, almost all oils and organic solvents, but it is resistant to strong acids, strong bases, chlorine free radicals and other substances that can react with the film

(such as borax, boric acid, some dyes, etc.) cannot contact with water-soluble films.